Electrical Program

Purpose and Objective

To establish requirements and procedures for the examination, installation, use and testing of continuity and resistance of electrical power tools, equipment, power cords and receptacles in order to prevent electric shock or other injuries resulting from direct/indirect electrical contact to employees working on or near energized or de-energized parts.

Definitions

Armored Cable – Type AC armored cable is a fabricated assembly of insulated conductors in a flexible metallic enclosure.

Askarel – A generic term for a group of nonflammable synthetic chlorinated hydrocarbons used as electrical insulating media. Askarels of various compositional types are used. Under arcing conditions the gases produced, while consisting predominantly of noncombustible hydrogen chloride, can include varying amounts of combustible gases depending upon the askarel type.

Attachment Plug (Plug cap)(Cap) – A device that, by insertion in a receptacle, establishes connection between the conductors of the attached flexible cord and the conductors connected permanently to the receptacle.

Cable Tray System – A unit or assembly of units or sections, and associated fittings, made of metal or other noncombustible materials forming a rigid structural system used to support cables. Cable tray systems include ladders, troughs, channels, solid bottom trays and other similar structures.

Conductor:

· Bare – A conductor having no covering or electrical insulation whatsoever.

· Covered – A conductor encased within material of composition or thickness that is not recognized as electrical insulation.

· Insulated – A conductor encased within material of composition and thickness that is recognized as electrical insulation.

Controller – A device or group of devices that serves to govern, in some predetermined manner, the electrical power delivered to the apparatus to which it is connected.

Device – A unit of an electrical system, which is intended to carry but not utilize electric energy.

Disconnecting Means – A device, or group of devices, or other means by which the conductors of a circuit can be disconnected from their source of supply.

Disconnecting (or Isolating) Switch (Over 600 volts, nominal) – A mechanical switching device used for isolating a circuit or equipment from a source of power.

Enclosure – The case or housing of apparatus; or the fence or walls surrounding an installation to prevent personnel from accidentally contacting energized parts, or to protect the equipment from physical damage.

Equipment – A general term including material, fittings, devices, appliances, fixtures, apparatus and the like, used as a part of, or in connection with, an electrical installation.

Flash Hazard – A dangerous condition associated with the release of energy caused by an electric arc.

Flash Hazard Analysis – A study investigating a worker’s potential exposure to arc-flash energy, conducted for the purpose of injury prevention and the determination of safe work practices and the appropriate levels of PPE.

Flash Protection Boundary – An approach limit at a distance for exposed live parts within which a person could receive a second degree burn if an electrical arc flash were to occur.

Grounded – Connected to earth or to some conducting body that serves in place of the earth.

Grounding Conductor – A conductor used to connect equipment or the grounded circuit of a wiring system to a grounding electrode or electrodes.

Grounding Conductor, Equipment – The conductor used to connect the non-current-carrying metal parts of equipment, raceways, and other enclosures to the system grounded conductor and/or the grounding electrode conductor at the service equipment or at the source of a separately derived system.

Grounding Electrode Conductor – The conductor used to connect the grounding electrode to the equipment grounding conductor and/or to the

grounded conductor of the circuit at the service equipment or at the source of a separately derived system.

Ground-Fault Circuit-Interrupter – A device whose function is to interrupt the electric circuit to the load when a fault current to ground exceeds some predetermined value that is less than that required to operate the overcurrent protective device of the supply circuit.

Labeled – Equipment is “labeled” if there is attached to it a label, symbol, or other identifying mark of a nationally recognized testing laboratory which: (a) makes periodic inspections of the production of

such equipment and (b) whose labeling indicates compliance with nationally recognized standards or tests to determine safe use in a specified manner.

Limited Approach Boundary – An approach limit at a distance from an exposed live part within which a shock hazard exists.

Listed – Equipment is “listed” if it is of a kind mentioned in a list that (a) is published by a nationally recognized laboratory, which makes periodic inspection of the production of such equipment, and (b) states such equipment meets nationally recognized standards or has been tested and found safe for use in a specified manner.

Overcurrent – Any current in excess of the rated current of equipment or the ampacity of a conductor. It may result from overload (see definition), short circuit or ground fault. A current in excess of rating may be accommodated by certain equipment and conductors for a given set of conditions. Hence the rules for overcurrent protection are specific for particular situations.

Overload – Operation of equipment in excess of normal, full load rating, or of a conductor in excess of rated ampacity which, when it persists for a sufficient length of time, would cause damage or dangerous overheating. A fault, such as a short circuit or ground fault, is not an overload.

Prohibited Approach Boundary – An approach limit at a distance from an exposed live part within which work is considered the same as making contact with the live part.

Raceway – A channel designed expressly for holding wires, cables, or busbars, with additional functions as permitted in this subpart. Raceways may be of metal or insulating material, and the term includes rigid metal conduit, rigid nonmetallic conduit, intermediate metal conduit, liquid-tight flexible metal conduit, flexible metallic tubing, flexible metal conduit, electrical metallic tubing, underfloor raceways, cellular concrete floor raceways, cellular metal floor raceways, surface raceways, wireways and busways.

Receptacle – A contact device installed at the outlet for the connection of a single attachment plug. A single receptacle is a single contact device with no other contact device on the same yoke. A multiple receptacle is a single device containing two or more receptacles.

Restricted Approach Boundary – An approach limit at a distance from an exposed live part within which there is an increased risk of shock, due to electrical arc over combined with inadvertent movement, for personnel working in close proximity to live part.

Shock Hazard Analysis – A determination of the voltage to which personnel will be exposed, boundary requirement, and the personal protective equipment necessary in order to minimize the possibility of electric shock to personnel.

Shock Protection Boundaries – Identified as Limited, Restricted, and Prohibited Approach Boundaries are applicable to the situation in which approaching personnel are exposed to live parts.

Voltage (of a circuit) – The greatest root-mean-square (effective) difference of potential between any two conductors of the circuit concerned.

Voltage, nominal – A nominal value assigned to a circuit or system for the purpose of conveniently designating its voltage class (as 120/240, 480Y/277, 600, etc.). The actual voltage at which a circuit operates can vary from the nominal within a range that permits satisfactory operation of equipment.

Voltage to ground – For grounded circuits, the voltage between the given conductor and that point or conductor of the circuit that is grounded; for ungrounded circuits, the greatest voltage between the given conductor and any other conductor of the circuit.

Wireways – Sheet-metal troughs with hinged or removable covers for housing and protecting electric wires and cable, and in which conductors are laid in place after the wireway has been installed as a complete system.

General Requirements

All electric equipment, conductors, etc. and the installation of such equipment, conductors, etc. used to provide electric power and light for employee workplaces shall be designed and installed in accordance with the safety standards contained in 29 CFR § 1910.302 through 1910.308.

All electrical equipment shall be examined/inspected routinely to ensure that no recognizable hazards exist that are likely to cause death or serious physical harm to employees. Examinations and inspections shall be based on the following:

· The suitability of equipment for the application, based on listing or labeling of equipment.

· Wire-bending and connection space.

· The classification of equipment, conductors, etc. by type, size, voltage, current capacity, etc.

· The mechanical strength and durability of the equipment for the application, including the protection afforded by enclosures, cabinets, etc.

· The insulation.

· The effects of heating and/or arcing under load.

· The classification by type, size, voltage, current capacity, and specific use.

· Other factors which are designed to provide protection to employees using or likely to come in contact with the equipment.

All electrical equipment shall be approved equipment that has been tested and certified by a Nationally Recognized Testing Laboratory

(NRTL) recognized by OSHA and labeled. It shall be installed and used in accordance with the information contained in the listing and/or labeling. The following information shall be permanently affixed to and readily visible on all electrical equipment:

· Manufacturer’s name, trademark, etc.

· Voltage, current, wattage, or other ratings as necessary.

When work is to be performed on or around electrical equipment, the following shall be maintained in accordance with 29 CFR § 1910.303:

· Guarding and enclosing of energized components, parts, etc. of electrical equipment.

· Sufficient access and working space provided and maintained about all electrical equipment to permit ready and safe operations and maintenance.

· Entrances and access to workspace.

· Illumination.

All electrical equipment shall be designed, specified, installed and used in accordance with 29 CFR § 1910.304, the National Electrical Code (NEC) and the National Fire Protection Association, Inc. (NFPA) 70E, Standard for Electrical Safety in the Workplace.

All unused openings (including conduit knockouts) in electrical enclosures and fittings shall be closed with appropriate covers, plugs or plates.

All electrical enclosures such as switches, receptacles and junction boxes shall be provided with tight-fitting covers or plates.

All electrical raceways and enclosures shall be securely fastened in place.

All electrical conductors shall be color-coded in a consistent manner. The grounded conductor and the equipment-grounding conductor shall be identifiable and distinguishable from all other conductors.

All electrical circuits and equipment shall be grounded by means of either electrical circuit or system grounding or electrical equipment grounding in accordance with 29 CFR § 1910.304.

All metal cable trays, metal raceways and metal enclosures for conductors shall be grounded.

All metal enclosures for service equipment shall be grounded.

The exposed non-current-carrying metal parts of fixed equipment that may become energized shall be grounded:

· If the equipment is subject to employee contact within eight (8) feet vertically or five (5) feet horizontally of ground or grounded metal objects.

· If the equipment is located in wet or damp environments.

· If the equipment is in electrical contact with metal.

· If the equipment is supplied current by a metal-clad, metal-sheathed or grounded metal raceway wiring method.

· If the equipment operates with any terminal at over 150 volts to ground, with the following exceptions:

o Enclosures for switches or circuit breakers used for other than service equipment and accessible to qualified persons only.

o Metal frames of electrically heated appliances that are permanently and effectively insulated from ground.

o The cases of distribution apparatus such as transformers and capacitors on wooden poles at a height of more than eight (8) feet above ground or grade level.

All non-current-carrying metal parts of equipment that are supplied current by a cord and plug shall be grounded, unless:

· The equipment is supplied through an isolating transformer with an ungrounded secondary of not more than 50 volts.

· The portable tool is double insulated and distinctively marked accordingly.

The metal parts of the following non-electric equipment shall be grounded:

· The frames and tracks of electrically powered/operated cranes.

· Metal enclosures around equipment with over 750 volts between conductors.

The equipment grounding conductor used to ground the non-current-carrying metal parts of equipment shall either be a conductor running with the power conductors within the same raceway, cable, or cord, or shall be the metal conduit that encloses the power conductors.

Electrical equipment, components and wiring methods shall conform to the standards of 29 CFR § 1910.305.

Temporary wiring shall conform to the standards of 29 CFR § 1910.305.

Flexible cables and cords shall not be used in lieu of fixed or permanent wiring, except for the following exceptions:

· Pendants.

· Wiring of fixtures.

· Connection of portable lamps or appliances.

· Wiring of cranes and/or hoists where flexibility is necessary for operation.

· Connection of stationary equipment that requires frequent interchange or moving.

· Prevention of the transmission of vibration, where vibration tends to fatigue fixed wiring.

· Appliances where the fastening means and mechanical connections are designed to facilitate removal for maintenance and/or repair, such as exhaust fans,

water coolers, etc.

· Data processing cables that are approved as a part of a data processing system.

· Surge protection strips designed to protect data processing equipment.

Where allowed for use, flexible cables and cords shall not:

· Run through holes in walls, ceilings, floors, etc.

· Run through doorways, windows or similar openings.

· Be attached to building surfaces with such devices as staples, nails, wire, etc.

· Be concealed behind walls, ceilings, floors, etc.

Standard National Electrical Manufacturer’s Association (NEMA) plugs and receptacles shall be used on all cords and cables and shall be used jointly or separately as specified by NEMA specifications.

All conductors and electrical equipment shall be protected from overcurrent.

No electrical equipment, switches and wiring shall carry a load greater than that for which they are rated and as permitted by the National Electrical Code (NEC).

Overcurrent protection of circuits and conductors shall not be modified beyond that allowed in the installation safety requirements for overcurrent protection, 29 CFR §1910.304 (e) and (f).

A disconnecting means (disconnect switch) shall be provided and located within sight of the controllers of all motors. The disconnecting means

shall plainly indicate whether it is in the open (off) or closed (on) position. Disconnects for motor branch circuits exceeding 600 volts are not required in site of the controller; however, all installations using this exception shall conform to the standards of 29 CFR § 1910.305.

All motors, motor-control apparatus, and motor branch-circuit conductors shall be protected against overheating due to motor overloads or failure to start, against short-circuits and against ground faults.

All disconnect switches and overcurrent devices shall be legibly and permanently marked to indicate their purpose.

The energized parts of all motors and/or controllers operating at 50 volts or more between terminals shall be guarded to protect employees from accidental contact by one of the following methods:

· Installed in a room or enclosure that is accessible only to qualified persons.

· Installed on a balcony, gallery or other platform that is elevated and arranged to exclude unqualified persons.

· Elevated eight (8) feet or more above the floor.

The following requirements shall apply to transformers:

· Warning signs shall be affixed to the equipment or structure and shall note the operating voltage of exposed energized parts of transformer installations.

· Oil-insulated transformers that are installed indoors and that present a fire hazard, and dry-type, high fire point liquid-insulated and askarel-insulated transformers that are installed indoors and rated over 35kV, shall be installed in a vault designed to contain the fire and/or combustible liquids and to prevent unauthorized access.

· Vault doors shall be designed to be opened from inside the vault.

· Materials shall not be stored in transformer vaults.

· Piping or duct systems shall not pass through or enter transformer vaults.

· Safeguards shall be taken to eliminate the possibility of combustible materials, buildings, fire escapes and door and window openings from catching fire due to fires that may originate in oil-insulated transformers attached to or adjacent to the buildings or combustible materials.

Capacitors shall be equipped with an automatic discharge device or a device that will drain the capacitor’s charge when the circuit is de- energized.

All electrical safety-related work practices prescribed in 29 CFR § 1910.333 - .335 shall be followed by those persons performing work on

or near electrical equipment. Personnel shall employ safety-related work practices to prevent electrical shock, electrical arc-flash, electrical arc- blast and/or other injuries that may result from coming in direct or indirect contact with electrically energized components.

Employees having to work on or near energized electrical equipment/components/circuits shall de-energize the electrical equipment/components/circuits by following the procedures established for Lockout/Tagout. Refer to Lockout/Tagout.

Only qualified persons (electricians) shall be allowed to perform testing on electric circuits and/or equipment. Only electricians shall be allowed to work on electric circuits or equipment that has not been de-energized. Electricians shall be capable of working safely on energized circuits and shall be familiar with the proper use of special precautionary techniques, personal protective equipment, insulating and shielding materials and insulated tools. Our procedure for working on energized parts is listed below:

· Prior to any work on energized circuits, the maintenance superintendent with the assistance of the electricians verifies that: (a) de-energizing the part would introduce additional or increased hazards, or (b) de-energizing the parts is infeasible due to equipment design or operational limitations. This is documented on our Energized Electrical Work Permit (included in this section) along with the authorization prior to any work on energized circuits. (Note: Work performed on or near live parts by electricians related to tasks such as testing, troubleshooting, voltage measuring, etc., shall be permitted to be performed without an energized electrical work permit, provided appropriate safe work practices and personal protective equipment are utilized.) NFPA 70E Table 130.7(C)(9)(a) Hazard/Risk Category Classifications will be utilized for selection of appropriate personal protection equipment, included in this section

· During work on energized circuits, the electrician uses safety-related work practices to protect himself/herself and other employees who may be exposed to electrical hazards to ensure compliance with 29 CFR § 1910.333 (c).

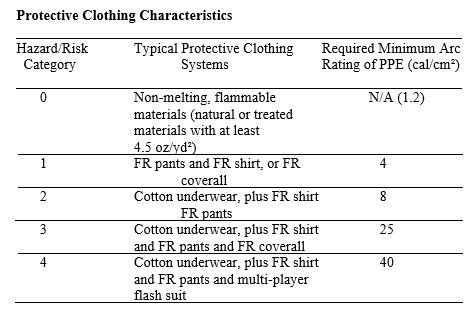

· Electricians working on or near energized electrical equipment wear protective clothing per Protective Clothing Characteristics Chart below:

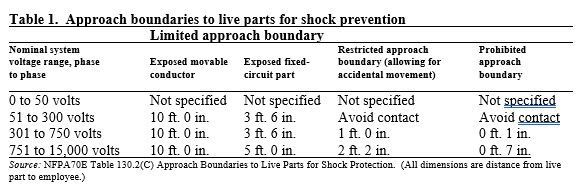

Approach distances to exposed live parts: The National Fire Protection Association defines three approach distances for shock hazards and one for arc flash.

Electric Shock (see Table 1)

· The limited approach boundary is the closest distance an unqualified person can approach, unless accompanied by a qualified person.

· The restricted approach boundary is the closest distance to exposed live parts a qualified person can approach without PPE and tools. Inside this boundary, accidental movement can put a part of your body or conductive tools in contact with live parts or inside the prohibited approach boundary. To cross the restricted approached boundary, the qualified person must:

o Have a documented plan that is approved by the production manager and/or safety director

o Use PPE suitable for working near exposed live parts and rated for the voltage and energy level involved.

o Be certain that no part of the body enters the prohibited space.

o Minimize the risk from unintended movement, by keeping as much of the body as possible out of the restricted space; body parts in the restricted space should be protected.

· The prohibited approach boundary is the minimum approach distance to exposed live parts to prevent flashover or arcing. Approaching any closer is comparable to making direct contact with a live part. To cross the prohibited approach boundary, the qualified person must:

o Have specified training to work on exposed live parts.

o Have a completed Energized Electrical Work Permit with proper written work procedures and justification of the need to work that close that has been approved by the fabrication/facilities support manager and safety coordinator.

o Use PPE appropriate for working near exposed live parts and rated for the voltage and energy level involved.

Arc flash. The flash protection boundary is the distance at which PPE is needed to prevent incurable burns (2nd degree or worse) if an arc flash occurs. (One still can get 1st or 2nd degree burns.) For systems of 600 volts and less, the flash protection boundary is 4 feet, based on an available bolted fault current of 50 kA (kilo amps) and a clearing time of 6 cycles (0.1 seconds) for the circuit breaker to act, or any combination of fault currents and clearing times not exceeding 300 kA cycles.

Employees shall open disconnecting means (move disconnect switches to the off position) before fuses are replaced.

Employees shall not work alone on energized lines or equipment over 600 volts.

The cords and plugs of portable electric equipment and flexible cord sets (extension cords) including their receptacle and plug shall be visually inspected on every shift before use.

The following tests shall be performed on all cord-and plug-connected equipment required to be grounded and on all cord sets and receptacles that are not a part of the permanent wiring of a building or structure:

· Equipment grounding conductors shall be tested for continuity and shall be electrically continuous.

· Each receptacle and attachment cap or plug shall be tested for correct attachment of the equipment grounding conductor. The equipment grounding conductor shall be connected to its proper terminal.

These tests shall be performed:

· Before first initial use.

· Before equipment is returned to service following any repairs.

· Before equipment is used after any incident, which can be reasonably suspected to have caused damage such as, being run over by a vehicle.

· At intervals not to exceed three (3) months, except those cord sets and receptacles that are fixed and not exposed to damage shall be tested at intervals not exceeding six (6) months.

Equipment that has not been tested as specified above shall not be used until such time as the equipment has been tested and shown to be safe.

The results of all performed tests shall be recorded and kept on file in the Safety Department. This test record shall identify each receptacle, cord set, and cord- and plug-connected equipment that passed the test. This record shall be kept by means of a log and a colored tape system. This record shall indicate the last date the equipment was tested and/or the interval for which it was tested and the color of the tape used for the respective cycle of testing. A different color tape shall be used for each successive cycle of testing (black tape is not an acceptable color). Refer to the “Electrical Equipment Test Documentation Form” (included in this section).

Cords and/or plugs that are found to be damaged (frayed or deteriorated insulation) and/or defective shall be removed from service until repaired. Flexible cords and cables shall be free of splices or taps. Cords and plugs that can not be repaired shall be destroyed and replaced.

Flexible cords shall not be fastened with staples, nails, etc. or otherwise hung in such a manner as to cause damage to the outer insulation of the

cords.

All flexible cords shall contain an equipment grounding conductor and appropriate plugs/receptacles to ensure proper continuity of the equipment grounding conductor at the point of attachment to fixed receptacles.

Ground-fault circuit-interrupters (GFCI) shall be installed on:

· All 125-volt, single-phase, 15- and 20-ampere receptacles installed in bathrooms or on rooftops or other wet locations.

· Each temporary 15 or 20 ampere, 120 volt AC circuit at locations where construction, demolition, modifications, alterations or excavations are being performed.

· All electrical circuits used in conjunction with portable electrical equipment and flexible power cords (extension cords).

The installation of ground-fault circuit-interrupters (GFCIs) shall be progressively introduced at all operations and installation progress shall be monitored to ensure the timely installation of all required GFCIs.

All portable electrical equipment shall be protected by ground-fault circuit-interrupters (GFCIs).

GFCIs shall be tested in accordance with the manufacturer’s recommendations. (Underwriters Laboratories recommends GFCIs be tested once a month and after any violent thunderstorm.) Testing shall be documented on the “Monthly GFCI Test Documentation Form” (included in this section) and records maintained in the Safety Department.

Portable electric equipment and flexible cords used in damp or wet work environments shall be approved for use in such environments.

Flammable materials that must be stored in small quantities shall be stored in properly labeled safety cans and in areas that are not within 25 feet of sources producing electric arcs.

Portable ladders shall be non-conductive construction if they are used in areas where they can contact exposed electrically energized components.

Jewelry and/or clothing that are conductive (not protected or insulated) shall not be worn if they can contact exposed electrically energized components.

Employees working in areas where electrical hazards exist shall use appropriate personal protective equipment, as defined in Personal Protective Equipment.

Personal protective equipment shall be maintained and periodically inspected/tested as outline in Personal Protective Equipment.

Employees working near exposed energized conductors or circuits shall use appropriate tools, including insulated tools, fuse pullers, non-conductive ropes, etc. Metal measuring tapes, ropes, handlines or similar devices with metallic thread woven into the fabric shall be prohibited.

Safety signs, safety symbols and accident prevention tags shall be used where required to warn personnel of electrical hazards that may endanger them.

Barricades shall be used in conjunction with safety signs where necessary to prevent or limit personnel access to work areas containing uninsulated energized conductors, components, etc.

Attendants shall be used to warn personnel of electrical hazards if signs and barricades do not provide sufficient warning and protection.

Monitoring and Enforcement – The safety coordinator shall be responsible for implementation and enforcement of this policy. Failure to follow established procedures or failure to use proper personal protective equipment can result in an employee receiving a safety violation notice, loss of safety incentive, and/or disciplinary action up to and including termination of employment.