Silica Exposure Prevention Program

Purpose and Objectives

The Silica Exposure Prevention Program is an important part of the company’s commitment to protect the health and safety of employees. It is written in accordance with OSHA’s final rule on Respirable Crystalline Silica, 29 CFR 1910.1053 and 1926.1153, and is intended to ensure that exposures are prevented.

Responsibilities

Respirable silica poses a significant risk. All personnel involved in operations that could potentially create silica dust must take specific actions to ensure that a hazard is not created.

The company is responsible for:

- Ensuring that all materials, and other resources required to fully implement and maintain this exposure prevention program, are readily available where and when they are required.

- Providing a site-specific health and safety plan for each project that outlines the work in detail along with the methods and practices that will be followed on each site. Considerations will include:

- Availability and delivery of all required tools and equipment

- Scope and nature of grinding/demolition work to be conducted

- Control methods to be used

- Level of respiratory protection required

- Coordination plan

- Conducting a periodic review of the effectiveness of the exposure prevention program. That includes a review of the available dust-control technologies to ensure they are selected and used when needed.

- Initiating the sampling of worker exposure to silica when there are non-standard work practices for which the control methods are not proven to be adequately protective.

- Ensuring that all required tools, equipment, and personal protective equipment are readily available and used as required by the site-specific health and safety plan.

- Ensuring supervisors and workers are educated and trained to an acceptable level of competency.

- Maintaining records of training, respirator fit-test results, crew safety meetings, and inspections (equipment, PPE, work methods/practices).

- Coordinating the work with the primary contractor and other employers to ensure a safe work environment.

Supervisors are responsible for:

- Obtaining a copy of the site-specific health and safety plan and making it available at the worksite.

- Selecting, implementing, and documenting the appropriate site-specific control measures.

- Providing adequate instruction to workers on the hazards of working with silica-containing materials (e.g., concrete), and on the precautions specified in the job-specific plan covering hazards at the location.

- Ensuring that workers have been fit-tested, are using the proper respirators, and that the results are recorded.

- Directing the work in a manner that ensures the risk to workers is minimized and adequately controlled.

- Communicating with the primary contractor and other sub-contractors where applicable to ensure a safe work environment.

The employees are responsible for:

- Knowing the hazards of silica dust exposure (after training has occurred).

- Using the assigned protective equipment in an effective and safe manner.

- Setting up the operation in accordance with the site-specific safety plan.

- Following established work procedures as directed by the supervisor.

- Reporting any unsafe conditions or acts to the supervisor.

- Knowing how and when to report exposure incidents.

The Health and Safety Director is responsible for reviewing and evaluating the effectiveness of the written exposure plan at least annually and:

- Updating as necessary

- Conducting frequent and regular inspections of job sites, materials, and equipment to implement the written exposure prevention program

- Providing access to SDSs of materials containing silica in accordance with 29 CFR 1910.1200

- Training employees in accordance with 29 CFR 1910.1053 and 1926.1153

Definitions

Action Level: A concentration of airborne respirable crystalline silica of 25/µg/m3, calculated as an 8-hour time-weighted average which requires preventative action to be taken by the employer.

Contamination Reduction Zone (CRZ): The work zone which represents the transition area between the exclusion zone and the support zone.

Exclusion Zone (EZ): The work zone which represents the area of highest contamination at the site and/or the area with the greatest risk of exposure to safety hazards including silica.

Permissible Exposure Limit (PEL): The maximum amount or concentration of a chemical that a worker may be exposed to under OSHA regulations as a time-weighted average.

Physician or Other Licensed Health Care Professional (PLHCP): An individual whose legally permitted scope of practice allows him or her to independently provide, or be delegated the responsibility to provide, some or all of the necessary health care services required.

Respirable Crystalline Silica: Quartz, cristobalite, and/or tridymite contained in airborne particles that are determined to be respirable by a sampling device designed to meet the characteristics for respirable-particle size.

Silicosis: Lung fibrosis caused by the inhalation of dust containing silica.

Support Zone: The work zone just outside the contamination reduction zone which represents the clean areas established at the site.

Silica Background Information

Crystalline silica is a basic component of soil, sand, granite, and many other minerals. Quartz is the most common form of crystalline silica. Cristobalite and tridymite are two other forms of crystalline silica. All three forms may become respirable-sized particles when workers chip, cut, drill, or grind objects that contain crystalline silica.

Silica is a one of several chemicals included in the larger classification of silicon dioxide (SiO2). Silicon dioxide is a chemical compound that includes crystalline silica (sand and quartz), amorphous silica (noncrystalline), and silicates (aluminum silicate). Crystalline silica is the basic component of sand, quartz, and granite rock. That form of silica is obtained from the Earth’s crust through mining. Crystalline silica can be processed into other materials including silica flour. Silica flour is produced through the milling of crystalline silica into a fine powder.

Silicates are compounds that contain silicon dioxide and elements such as aluminum, iron, potassium, magnesium, and/or calcium. Silicates exist in fibrous and non-fibrous forms. Examples of non-fibrous forms include Portland cement, talc, mica, soapstone, and clays.

At least 1.7 million U.S. workers are exposed to respirable crystalline silica in a variety of industries and occupations including construction, sandblasting, and mining. Silicosis, an irreversible but preventable disease, is the illness closely associated with occupational exposure to the material which also is known as silica dust. Occupational exposures to respirable crystalline silica are associated with the development of silicosis, lung cancer, pulmonary tuberculosis, and airways diseases. Those exposures may also be related to the development of autoimmune disorders, chronic renal disease, and several other adverse health effects.

Health Hazards

Crystalline silica dust can cause a chronic, sometimes disabling, and even fatal disease called silicosis. The fine particles are deposited in the lungs which causes a thickening and scarring of the lung tissue. The scar tissue restricts the ability of the lungs to extract oxygen from the air. This damage is permanent but symptoms of the disease may not appear for many years.

A worker may develop any of three types of silicosis, depending on the concentrations of silica dust and the duration of exposure:

- Chronic Silicosis — develops after 10 or more years of exposure to crystalline silica at relatively low concentrations

- Accelerated Silicosis — develops 5 to 10 years after initial exposure to crystalline silica at high concentrations

- Acute Silicosis — develops within a few weeks, or 4 to 5 years, after exposure to very high concentrations of crystalline silica

Initially, workers with silicosis may have no symptoms. However, as the disease progresses, a worker may experience:

- Shortness of breath

- Severe cough

- Weakness

Exposure to silica has also been linked to other diseases, including bronchitis, tuberculosis, and lung cancer.

Hazard Identification

In order to protect workers from hazardous silica dust, the site-specific health and safety plan will identify tasks in which silica may become airborne and become a risk. Those activities may include but are not limited to:

- Chipping, hammering, and drilling of rock

- Crushing, loading, hauling, and dumping of rock

- Abrasive blasting using an abrasive containing silica or sand

- Abrasive blasting of or on concrete (regardless of the abrasive used)

- Sawing, hammering, drilling, grinding, and chipping of concrete or masonry

- Demolition of concrete and masonry structures

- Dry sweeping or pressurized air blowing of concrete, rock, or sand dust.

As conditions change on the jobsite, the identification of potential silica exposure to workers should be examined.

Exposure Assessments

Exposure assessments must be conducted for employees who may potentially be exposed to crystalline silica at or above the action level. Assessments may be performed by conducting personal monitoring or taking a representative sample from employees working in the same area and conducting similar tasks.

Exposure assessments should only be conducted by trained and qualified individuals who understand industrial hygiene techniques.

The exposure assessment will be conducted using sampling methods which assess the 8-hour TWA exposure for each employee. Exposure monitoring should be conducted initially and breathing zone air samples should be used that are reflective of the exposure of employees on each shift, job classification, and in each work area. In cases where several employees conduct the same task, a representative fraction of these employees will participate in sampling in order to meet the requirement.

Based on the results of initial sampling, if monitoring indicates that the employee exposures are below the action level, monitoring will be discontinued for those tasks and work areas that were sampled.

If sampling results indicate that exposures are at or above the action level (AL), but below the permissible exposure limit (PEL), the monitoring shall be repeated within six months of the most recent monitoring.

When sampling results indicate that exposures are above the PEL, monitoring will be repeated within three months of the most recent monitoring. Employees must also be informed of those sampling results in writing within 15 working days after completing the exposure assessment. Whenever an exposure assessment indicates that exposures are above the PEL, the employer shall describe in written notification the corrective action being taken to reduce employee exposures.

After repeat monitoring has taken place (non-initial), and results indicate that employee exposures are now below the action level, the monitoring shall be repeated within six months. This sampling will be repeated until two consecutive measurements, taken seven or more days apart, are consistently below the action level. At that point, monitoring may be discontinued.

If there is a change in the production, process, exposure control equipment, personnel, or work practices that may be expected to result in new or higher potential exposures, sampling shall be conducted again to verify that exposure to silica is adequately controlled.

Engineering Controls, Work Practices & Respiratory Protection

The tables below outline the OSHA-required engineering controls, work practices, and respiratory protection minimum assigned protection factor for workers who are exposed to silica during specific activities. For clarification, NIOSH n95 respirators are appropriate for APF 10 respiratory protection factors.

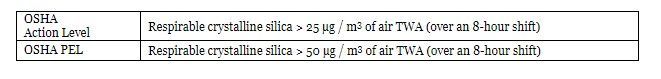

- OSHA Action Level - Respirable crystalline silica > 25 µg / m3 of air TWA (over an 8-hour shift).

- OSHA PEL – Respirable crystalline silica > 50 µg / m3 of air TWA (over an 8-hour shift).

Engineering controls will be used to limit worker exposure to respirable crystalline silica, provide respirators when engineering controls cannot adequately limit exposure, limit worker access to high exposure areas, develop a written exposure prevention program, offer medical exams to highly exposed workers, and train workers on silica risks and how to limit exposures.

Medical exams will be provided to monitor workers who are required to wear a respirator for more than 30 days a year as a result of exposure to respirable silica and give them information about their lung health.

Company Specific and Task Specific Exposures and Controls

| Position | Job Duties | To minimize silica exposure | Respirator Guidance | Controls Used |

|---|---|---|---|---|

| Housekeeping | Shoveling, sweeping | Water and/or sweeping compound | No respirators are required during normal operations | Lightly mist piles of clay. Use always sweeping compound when cleaning floors. |

| Jackhammer and handheld chipping tools | Removal of concrete | Integrated water delivery system | Outdoor use less than or for 4 hours – no respirator required. If over 4 hours – use APF 10 respirator. Indoors use APF 10 respirator. | Ensure that water supply to the jackhammer is turned on and operational before starting the jackhammer. Ensure that water nozzles are working and aimed correctly at area. Ensure that water is flowing to the area prior to the jackhammer contacting the concrete. |

| Mill Line Drum Dust Collector | Use when adding dry bagged slurry mix ingredients | Mill Line Drum Dust Collector hood with wet/dry vacuum | No respirators are required during normal operations. | Ensure dust collector hood is placed firmly on drum. Ensure that hose is firmly attached to the drum dust collector and the wet/dry vacuum. Ensure that the vacuum is operating. Bags of dry mix must be below the drum dust collector inside the drum when emptied to minimize dust. |

| General Plant Housekeeping | Floor Cleaning | Use Sweeping Compound, wet dust suppression using water hoses and squeegees, HEPA vacuum or the mobile sweeper. NO DRY SWEEPING OR USING COMPRESSED AIR! | No respirators are required during normal operations. | Ensure enough sweeping compound is down before sweeping. Ensure that water is flowing before any sweeping is done if using wet method. |

| Hammermill (Crushing and Machine) | Mixing Plant | Enclosure with Local Exhaust Ventilation (LEV) System, belting and/or plastic stripping and maintaining a proper seal | No respirators are required during normal operations. | Ensure that the LEV air volume is maintained for negative pressure. Ensure that the Hammermill seal is maintained. . |

| Conveyors, Chutes and Transfer points | Mixing Plant | Covered Conveyors, wider belting, minimize chute fall height, plastic stripping with head enclosure at transfer points. | No respirators are required during normal operations. | Ensure that covers on conveyors are secure and in place. Ensure plastic stripping is secure and in place. |

| Maintenance | Mixing Plant | Replacing shaker screen, belting, head and tail pulleys, seals on Hammermill or any maintenance activity that can or does create airborne dust. | No respirators are required during normal operations. | Minimize free fall of clay from heights by placing any buildup of clay in a five-gallon bucket and lowering it to the floor to a co-worker to empty and dampen the clay mix by lightly spraying water using a pump sprayer. |

| Housekeeping | Mixing Plant | Clearing clay mix from floor area with mobile mini skid-steer loader (Dingo Machine) that is operated to not create airborne dust. | APF 10 | Dingo machine operator scoops clay mix up from floor with the bucket lowered to the floor. The Dingo machine operator transport the bucket of clay to the waste clay pile with the bucket as low to the floor as possible. The Dingo machine operator will raise the bucket only as high as needed to empty the clay from the bucket |

| Mobile Equipment (enclosed cab) Operator | Mixing Plant | Operates equipment moving clay mix materials, sand and brick material | No respirators are required during normal operations. | Ensure air conditioner filtration system is functioning properly. Maintain equipment’s door and window seals. Minimize dust sources in cab by using good housekeeping practices (keeping the inside of cab clean). |

| Mine and Plant Roadways | Mine Water Tanker | Operating water tanker wetting the roadways with water to control dust | No respirators are required during normal operations. | Ensure air conditioner filtration system is functioning properly. Maintain equipment’s doors and windows seals. Minimize dust sources in cab by using good housekeeping practices (keeping the inside of cab clean). |

| Kiln-Car Clean Off | Cleaning off Kiln Cars | No Sweeping. Use HEPA vacuum. | No respirators required during normal operations. | Ensure that the vacuum is always operating. |

| Breaking Down Kiln Cars | General Laborers | None | None | Kiln cars must be completely soaked down with a water hose. |

| Mixing Plant | Screw Auger for adding manganese and other bagged products to conveyor 2 | Enclosed chute from upper platform and plastic strips skirting on feeder to conveyor for bagged material | APF 10 | Ensure that the end of the bag containing the bagged product in fully inserted into the chute once it is opened. Ensure that the top of the chute is enclosed. Ensure that the contents of the bagged product have been fully emptied. Ensure that the empty bag is lightly folded to not release any remaining bagged material into the air. |

| Mixing Plant | Making deck block | Wet suppression | No respirators required during normal operations | Raw material must be wet down periodically to keep dust down at all times. |

| Mixing Plant | Emptying bags | Respirators must be worn at all times. | APF 10 | Respirators must be worn at all times. |

| Brick Making Moulding Lines | Sand Coating Area | Enclosed area with dust collector | No respirators are required during normal operations. | NO DRY BRUSHING/SWEEPING! NO COMPRESSED AIR! Ensure sliding doors are closed fully and doors and/or plastic strips are fully enclosing the back of enclosure area. Ensure dust collector filters are changed as needed to maintain efficiency. |

| Brick Making Moulding Lines | Pug Tub Catwalk | Removing clay mix from catwalk | No respirators are required if these work practices are followed | Ensure enough water mist from pump sprayer is sprayed on clay mix to control dust while using shovel to scoop up clay mix and placing in bucket and lowered to floor to co-worker who will empty bucket into dumpster. OR Use vacuum with properly installed HEPA filter. NO SHOVELING FROM UPPER CATWALK TO FLOOR LEVEL. NO COMPRESSED AIR. |

| Brick Making Moulding Lines | Kiln Car Clean Off | Removing debris from top of kiln car | No respirators are required during normal operations | Use vacuum with properly installed HEPA filter or vacuum system. NO DRY SWEEPING! NO COMPRESSED AIR! |

| Brick Making Moulding Lines | Floor Person | Emptying forklift dumpsters and sand coating bags | No respirators are required if work practices are followed | Dumpsters and bags are to be emptied at ground level (Never from an upper level) with the forklift mask height as low as possible to minimize blowback. |

| Sand Plant | Bag Filling Station | Fabric Filter Baghouse. Adding bagged products to sand and filling super sacks | APF 10 | Bagged product is placed on mixer grate under dust collector duct, bag is cut open and empty bag is held closely over mixer grate and slightly shook to empty any remaining product and then empty bag is folded up while on the grate. Folded empty bag in placed in plastic bag on the platform. Empty super sack fill spout is to be fully pulled onto the bag filler downspout with super sack on bag platform. Once super sack is filled make sure all flow is stopped before removing bag fill spout from downspout. Super sack fill spout is tied closed. Vacuum off any sand coating spillage on the outside of the super sack before moving it. Ensure that HEPA filters are correctly installed, and baghouse is operational. Vacuum up any spilled sand in the area. NO DRY SWEEPING! NO COMPRESSED AIR! |

| Sand Plant | Batching Area | Fabric Filter Baghouse | APF 10 | Ensure that HEPA filters are correctly installed, and baghouse is operational. Spilled sand and bagged products are to be vacuumed up. NO DRY SWEEPING! NO COMPRESSED AIR! |

| Sand Plant | General | General | APF 10 | Sand Plant employees must rotate regularly throughout the day when emptying bags, operating the mixer and batching area. Sand plant employees can only empty (2) bags of sand (supersacks) per day unless supersacks are wetted down. |

| Stationary Masonry Saws | Brick Mason | None | None | Use saw equipped with integrated water delivery system that continuously feeds water to the blade. Operate and maintain tools in accordance with manufacturer’s instructions to minimize dust emissions. |

| Handset | General | Wet down brick near cutter area | None | Augusta brick must be wet down near cutter area |

| Plantwide | Operators | Filters must be cleanted out by using compressed air with ventilation system | None | Filters must be cleaned out by using compressed air with ventilation system |

OSHA Requirements (Action Level, PEL)

Effective June 23, 2016; and required by June 23, 2017:

Employees are required to follow the aforementioned guidelines. If conditions of the worksite prohibit the guidelines, or if the need arises, environmental monitoring will measure workers’ exposure to silica using OSHA/NMAM analytical methodology and independently decide which dust controls work best to limit exposures to below the PEL of respirable crystalline silica in the workplace. If the exposure is equal to or greater than 25 μg/m3 of respirable crystalline silica as an 8-hour TWA, then control measures must be implemented to protect the health and safety of the employees. If tasks are not listed on the aforementioned table, but are in practice very similar to the exposures listed above, then the required respiratory protection designated by the table will be used for that task.

Housekeeping

Employees will not dry sweep or dry brush material containing silica where such activity could contribute to employee exposure to respirable crystalline silica. Unless wet sweeping, HEPA-filtered vacuuming or other methods that minimize the likelihood of exposure are not feasible. Compressed air will not be used to clean clothing or surfaces where such activity could contribute to employee exposure to respirable crystalline silica. An exception is if the compressed air is used in conjunction with a ventilation system that effectively captures the dust cloud created by the compressed air; if not, no alternative method is feasible.

Medical Surveillance

When necessary, medical surveillance will be provided at no cost to the employee and at a reasonable time and place for each employee who is required to use a respirator for crystalline Silica under the provisions of this policy. All medical exams will be performed by a physician or other licensed health care professional (PLHCP).

Initial Examination

If an employee is reasonably estimated to be exposed to conditions which would require him or her to wear a respirator for crystalline silica for more than 30 days of the year, then the employee will be provided a baseline examination within 30 days after their initial assignment. That examination will consist of:

- An initial medical and work history with:

- Emphasis on past, present, and anticipated exposure to respirable crystalline silica, dust, and other agents affecting the respiratory system

- Any history of respiratory system dysfunction including signs and symptoms of respiratory disease (e.g., shortness of breath, cough, wheezing), a history of tuberculosis, and smoking status and history

- Physical examination with special emphasis on the respiratory system

- A chest X-Ray:

- A single posteroanterior radiographic projection or radiograph of the chest at full inspiration recorded on either film (no less than 14 x 17 inches and no more than 16 x 17 inches) or digital radiography systems, interpreted and classified according to the International Labour Office (ILO) International Classification of Radiographs of Pneumoconioses by a NIOSH-certified B Reader

- A pulmonary function test to include forced vital capacity (FVC) and forced expiratory volume in one second (FEV1) and FEV1/FVC ratio, administered by a spirometry technician with a current certificate from a NIOSH-approved spirometry course:

- Testing for latent tuberculosis infection

- Any other tests deemed appropriate by the PLHCP

Periodic Examinations

Medical examinations that include the aforementioned procedures at least every three years or more frequently if recommended by the PLHCP. The company will provide the PLHCP with:

- A copy of this plan

- A description of an employee’s former, current, and anticipated duties as they relate to the employee’s occupational exposure to respirable crystalline silica

- A description of any PPE used or to be used by the employee, including when and for how long the employee has used or will use that equipment

- Information from records of employment-related medical examinations previously provided to the employee and within the control of the employer

PLHCP’s Written Medical Opinion for the Employer

The company will obtain the medical opinion from the PLHCP within 30 days of the examination. As directed in the previous sections, the medical provider is required to provide:

- The date of the examination

- A statement that the examination has met the requirements of this section

- Any recommended limitations on the employee’s use of respirators

If the employee provides written authorization, the written opinion shall also contain either or both of the following:

- Any recommended limitations on the employee’s exposure to respirable crystalline silica

- A statement that the employee should be examined by a specialist if:

- The chest X-ray provided in accordance with this section is classified as 1/0 or higher by the B Reader, or if referral to a specialist is otherwise deemed appropriate by the PLHCP

The employer shall ensure that each employee receives a copy of the written medical opinion described above within 30 days of the examination performed

Additional Examinations

- If the PLHCP’s written medical opinion indicates that an employee should be examined by a specialist, the company will make available an examination within 30 days after receiving the PLHCP’s opinion.

- All pertinent medical records and information regarding exposure will be provided to the specialist.

- The specialist will be required to explain the results of the examination to the employee and provide him or her with a written medical report no more than 30 days after the examination.

Training

The company will develop and administer training that fulfills the requirements of the regulations.

After training, employees need to demonstrate knowledge and understanding of:

- Health hazards associated with exposure to respirable crystalline silica

- Specific tasks in the workplace that could result in exposure to respirable crystalline silica

- Specific measures that have been implemented to protect employees from exposure to respirable crystalline silica including engineering controls, work practices, and respirators to be used

- The hazards communication standards

- The identity of a competent person designated by the company

- The purpose and description of the medical surveillance program

Recordkeeping

The first directive of the company is to follow all engineering, work practices, and respiratory protection measures outlined in Table 1 to satisfy the requirements of this regulation. When instances arrive that are not covered by the Table 1 job descriptions, the Health and Safety Director will utilize previous industrial hygiene and risk assessment data. If that data is unavailable, the Health and Safety Director will complete air monitoring in accordance to the guidelines found in the regulation. If air monitoring occurs, the company will:

- Maintain an accurate record of all exposure measurements taken to assess employee exposure to respirable crystalline silica. That record will include:

- Date of measurement

- Task monitored

- Sampling and analytical methods used

- Number, duration, and results of samples taken

- Identity of the laboratory that performed the analysis

- Type of PPE worn by monitored employees

- Name, Social Security number, and job classification of all employees represented by the monitoring

- Exposure records maintained and made available in accordance 29 CFR 1910.1200 (the hazard communication standard)

- Maintain an accurate record of all objective data relied upon to comply with the requirements of the regulation. This record will include:

- The crystalline silica-containing material in question

- The source of the objective data

- The resting protocol and result of testing

- A description of the process, task, or activity on which the objective data were based

- Other data relevant to the process, task, activity, material, or exposures on which the objective data are based

- Objective data records maintained and made available in accordance the 29 CFR 1910.1200

- Maintain an accurate record for each employee covered by medical surveillance as required by the regulations. This record will include:

- Name and Social Security number of the employee

- A copy of the PLHCP’s and specialist’s written medical opinions

- A copy of the information provided to the PLHCPs and specialists

- Medical surveillance records maintained and made available in accordance the 29 CFR 1910.1200